Solar Basics

What is Solar Power?

Solar power is the conversion of sunlight into electricity, either directly using Photovoltaics (PV), or indirectly using concentrated solar power (CSP).

Photovoltaics were initially, and still are, used to power small and medium-sized applications, from the calculator powered by a single solar cell to off-grid homes powered by a photovoltaic array. They are an important and relatively inexpensive source of electrical energy where grid power is inconvenient, unreasonably expensive to connect, or simply unavailable. However, as the cost of solar electricity is falling, solar power is also increasingly being used even in grid-connected situations as a way to feed low-carbon energy into the grid.

Concentrated solar power systems use lenses or mirrors and tracking systems to focus a large area of sunlight into a small beam. Photovoltaics convert light into electric current using the photovoltaic effect.

Why Green Energy?

Green, or renewable, energy is generated by harnessing the power of the wind, sun and sea, or by burning replaceable sources such as waste products and crops (bio fuels).

Most renewable energy comes either directly or indirectly from the sun. Sunlight, or solar energy, can be used directly for heating and lighting homes and other buildings, for generating electricity, and for hot water heating, solar cooling, and a variety of commercial and industrial uses.

Renewable energy is important because of the benefits it provides. The key benefits are:

Sustainable Energy

Renewable energy will not run out ever. Other sources of energy are finite and will some day be depleted.

Environmental Benefits

Renewable energy technologies are clean sources of energy that have a much lower environmental impact than conventional energy technologies.

Jobs and the Economy

Most renewable energy investments are spent on materials and workmanship to build and maintain the facilities, rather than on costly energy imports. Renewable energy investments are usually spent within the United States, frequently in the same state, and often in the same town. This means your energy dollars stay home to create jobs and fuel local economies, rather than going overseas.

Energy Security

After the oil supply disruptions of the early 1970s, our nation has increased its dependence on foreign oil supplies instead of decreasing it. This increased dependence impacts more than just our national energy policy.

Domestic Solar Power System

Consumption Calculator

| Appliance Type | No. of Appliances | Wattage | Hours/day | Daily Units Consumed |

| Light Bulb | ||||

| CFL | ||||

| Light Tube | ||||

| Fan | ||||

| Electric Iron | ||||

| Motor Pump | ||||

| Laptop Computer | ||||

| Mobile/Tablet Charging | ||||

| Refrigerator | ||||

| TV with Set-top Box | ||||

| AC 1 Ton / Heater | ||||

| Water Geyser | ||||

| Total consumption per day (in Units) | 12.27 | |||

| Consumption per month (in Units) | 368.1 | |||

Panel Direction and Tilt Angle

India is located in the northern hemisphere but closer to the equator between latitudes 6˚ and 36˚N (the longitude boundaries are 68˚ and 98˚E). In order to get the most from solar panels, they must be pointed in the direction that captures most sunshine. In India, as anywhere in the northern hemisphere, solar panels should face southwards.

A solar collector or photovoltaic module collects the maximum solar radiation when the Sun’s rays strike it at right angles. As the solar collector or module is tilted away from perpendicular alignment to the Sun, less solar energy is received. However, small deviations away from the ideal tilt will not affect energy output much, and may be preferable from an appearance (as along the roof slope) or stability standpoint.

The optimal tilt angle for a solar energy system depends on both the latitude of the location and on nature of the application. Fixed modules and collectors that need to produce electricity and heat on a year-round basis are usually tilted at an angle equal to the latitude of the site. Hence for TamilNadu the tilt angle of the Solar Panel is 13 degrees as the latitudinal co-ordinate of TamilNadu is 13.09 degrees

Solar PV Modules

- The PV modules must conform to the latest edition of any of the following IEC / equivalent BIS Standards for PV module design qualification and type approval:

- Crystalline Silicon Terrestrial PV Modules: IEC 61215 / IS14286

- Thin Film Terrestrial PV Modules: IEC 61646 / Equivalent IS (Under Dev.)

- Concentrator PV Modules & Assemblies: IEC 62108

- In addition, the modules must conform to IEC 61730 Part 1: Requirements for Construction & Part 2: Requirements for Testing, for safety qualification or Equivalent IS (Under Dev.)

- PV modules to be used in a highly corrosive atmosphere (coastal areas, etc) must qualify Salt Mist Corrosion Testing as per IEC 61701 / IS 61701.

- IDENTIFICATION AND TRACEABILITY

Each PV module must use a RF identification tag (RFID), which must contain the following information:- Name of the manufacturer of PV Module

- Name of the Manufacturer of Solar cells

- Month and year of the manufacture (separately for solar cells and module)

- Country of origin (separately for solar cells and module)

- I-V curve for the module

- Peak Wattage, Im, Vm and FF for the module

- Unique Serial No and Model No of the module

- Date and year of obtaining IEC PV module qualification certificate

- Name of the test lab issuing IEC certificate

- Other relevant information on traceability of solar cells and module as per ISO 9000 series

- AUTHORIZED TESTING LABORATORIES/ CENTERS

PV modules must qualify (enclose test reports/certificate from IEC/NABL accredited laboratory) as per relevant IEC standard. Additionally the performance of PV modules at STC conditions must be tested and approved by one of the IEC / NABL Accredited Testing Laboratories including Solar Energy Centre. For small capacity PV modules upto 50Wp capacity STC performance as above will be sufficient. However, qualification certificate from IEC/NABL accredited laboratory as per relevant standard for any of the higher wattage regular module should be accompanied with the STC report/certificate. - WARRANTY

PV modules used in solar power plants/ systems must be warranted for their output peak watt capacity, which should not be less than 90% at the end of 12 years and 80% at the end of 25 years.\

Balance of System (BOS) Items / Components

- The BOS items / components of the SPV power plants/ systems deployed under the Mission must conform to the latest edition of IEC/ Equivalent BIS Standards/ MNRE specifications / as specified below:

**In case if the Charge controller is in-built in the inverter, no separate IEC 62093 test is required and must additionally conform to the relevant national/international Electrical Safety Standards wherever applicableBOS Item / System Applicable BIS/Equivalent IEC Standard or MNRE Specifications Standard Description Standard Number Solar PV Lighting Systems Solar PV Home Lighting System

Solar PV Street Lighting System

Solar PV LanternAs per MNRE latest specifications dated 09-09-2011 Solar PV Systems

(more than 100 Wp and up to 20 KWp Capacity only):

Charge Controller/MPPT units

Power Conditioners/ Inverters** including MPPT and ProtectionsEnvironmental Testing

Efficiency Measurements

Environmental TestingIEC 60068-2 (1,2,14,30) / Equivalent BIS Std.

IEC 61683 / IS 61683

IEC 60068-2 (1, 2, 14, 30) / Equivalent BIS StdStorage Batteries General Requirements & Methods of Testing Tubular Lead Acid / VRLA / GEL

Capacity Test

Charge/Discharge Efficiency

Self-DischargeAs per relevant BIS Std Cables General Test and Measuring Method PVC insulated cables for working voltage up to and including 1100 V and UV resistant for outdoor installation IEC 60227 / IS 694

IEC 60502 / IS 1554 (Pt. I & II)Switches/Circuit Breakers /Connectors General Requirements

Connectors – Safety

A.C. /D.CIEC 60947 part I,II, III / IS 60947 Part I,II,III

EN 50521Junction Boxes /Enclosures for Inverters/Charge Controllers/Luminaries General Requirements IP 54 (for outdoor) / IP 21 (for indoor) as per IEC 529 - AUTHORIZED TESTING LABORATORIES/CENTERS

Test certificates / reports for the BoS items/ components can be from any of the NABL/ IEC Accredited Testing Laboratories or MNRE approved test centers. The list of MNRE approved test centers will be reviewed and updated from time to time.

*Beyond 10KVA, self certification by the manufacturer is acceptable. - WARRANTY

The mechanical structures, electrical works including power conditioners/inverters/charge controllers/ maximum power point tracker units/distribution boards/digital meters/ switchgear/ storage batteries, etc. and overall workmanship of the SPV power plants/ systems must be warranted against any manufacturing/ design/ installation defects for a minimum period of 5 years.

Solar Panel Efficiency Comparison

Solar Panel Efficiency explained

Solar panel efficiency is the amount of sunlight (solar irradiance) that falls on the surface of a solar panel and is converted into electricity. Due to the many advances in photovoltaic technology over the last decade, the average panel conversion efficiency has increased from 15% to over 23%. This significant jump in efficiency resulted in the power rating of a standard residential solar panel increasing from 250W to over 450W.

As explained below, solar panel efficiency is determined by two main factors: the photovoltaic (PV) cell efficiency, based on the solar cell design and silicon type, and the total panel efficiency, based on the cell layout, configuration, and panel size. Increasing the panel size can improve efficiency by creating a larger surface area to capture sunlight, with the most powerful solar panels now achieving well over 700W power ratings.

What are the most efficient solar panels?

At present, monocrystalline panels are the most efficient type available. However, modern monocrystalline panels are manufactured using several different cell types, with the most efficient varieties built using high-performance N-type monocrystalline cells, enabling panels to reach up to 24.3% efficiency. The three main N-type cells include TOPcon, IBC, and HJT, described in detail below. Polycrystalline cells and panels are no longer manufactured due to their lower efficiency, which peaked at just over 18%. In recent years, virtually all leading solar panel manufacturers around the world have transitioned to producing more efficient solar panels built using monocrystalline N-type Heterojunction (HJT), TOPcon, or Back-contact (IBC) cells. Learn more about solar PV cell construction and the different cell types.

The solar cell type, design, and configuration all impact panel efficiency, with the N-type back-contact (IBC) cells being the most efficient.

Top 10 Most Efficient Residential Solar Panels 2024 *

| # | Make | Model | Power | Efficiency |

| 1 | Aiko Solar | Neostar 3N54 | 485 W | 24.3 % |

| 2 | Maxeon | Maxeon 7 | 445 W | 24.1 % |

| 3 | Aiko Solar | Neostar 2P | 475 W | 23.8 % |

| 4 | Recom Tech | Black Tiger Series | 460 W | 23.6 % |

| 5 | AEG | BC Premium | 460 W | 23.6 % |

| 6 | Longi Solar | Hi-Mo 6 Scientist | 455W | 23.3 % |

| 7 | Huasun Solar | Himalaya G12 | 450 W | 23.0 % |

| 8 | Canadian Solar | TOPHiKu6 | 470 W | 23.0 % |

| 9 | Jinko Solar | Tiger NEO | 460 W | 23.0 % |

| 10 | Winaico | WST-NGX-D3 | 450 W | 23.0 % |

* Last update: September 2024. Residential size panels – 54 to 66 cells (108-HC, 120-HC or 132-HC) and 96/104 cell formats. Does not include commercial panels greater than 2.0m in length

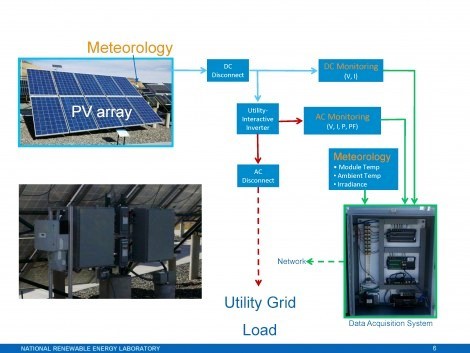

SCADA System

SCADA (supervisory control and data acquisition) is a system operating with coded signals over communication channels so as to provide control of remote equipment. The supervisory system may be combined with a data acquisition system by adding the use of coded signals over communication channels to acquire information about the status of the remote equipment for display or for recording functions.

The intuitive SCADA system enables utility-scale solar power plant owners to visualize the operation of their PV solar arrays. In addition to rapid commissioning and historical data reports, the information delivered by the SCADA provides the visibility to better manage your energy output and ensures your solar power plant meets grid requirements by maximizing system availability.

The SCADA system monitors PV plant performance by means of a mathematical model initialized at installation with plant design data: PV panels’ peak power, inverter specifications, manufacturer-provided electric parameters, number of strings, strings length, etc. The model is continuously fed with local weather data, and it calculates in real time the correct energy production at 100% plant capacity. The automatic comparison between the calculated and the real production figures – supplied by the data logger – gives a precise measure of plant performance and plant health every minute or less.